quasivoid

building transformers with EE cores and bobbins

I found very cheap, large packs of ferrite EE cores and bobbins in all kinds of sizes on AliExpress. Magnet wire is wrapped around the bobbin, which then has cores inserted into it. Tips on using these does not seem to be readily accessible. Here is what I found while playing with them at my bench.

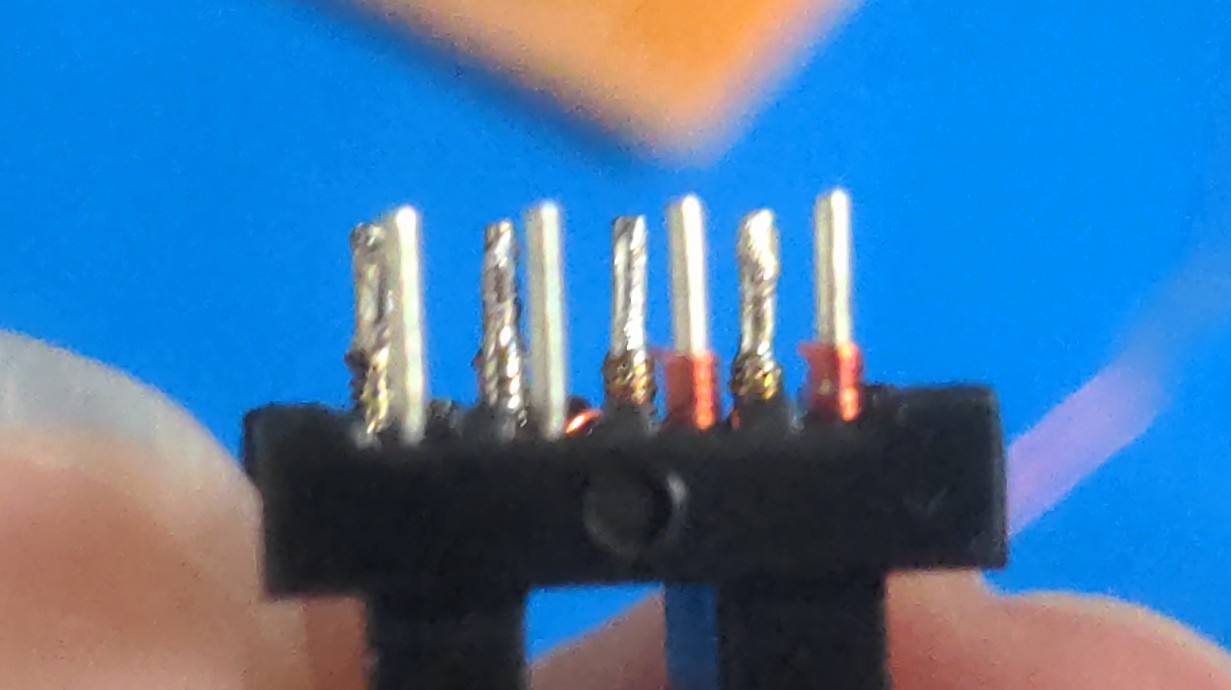

Keeping track of parameters like which pin is which inevitably requires planning and writing down your design first. A yellow POSCA marker does a decent job of marking the plastic. I used the lower dots to keep track of phasing.

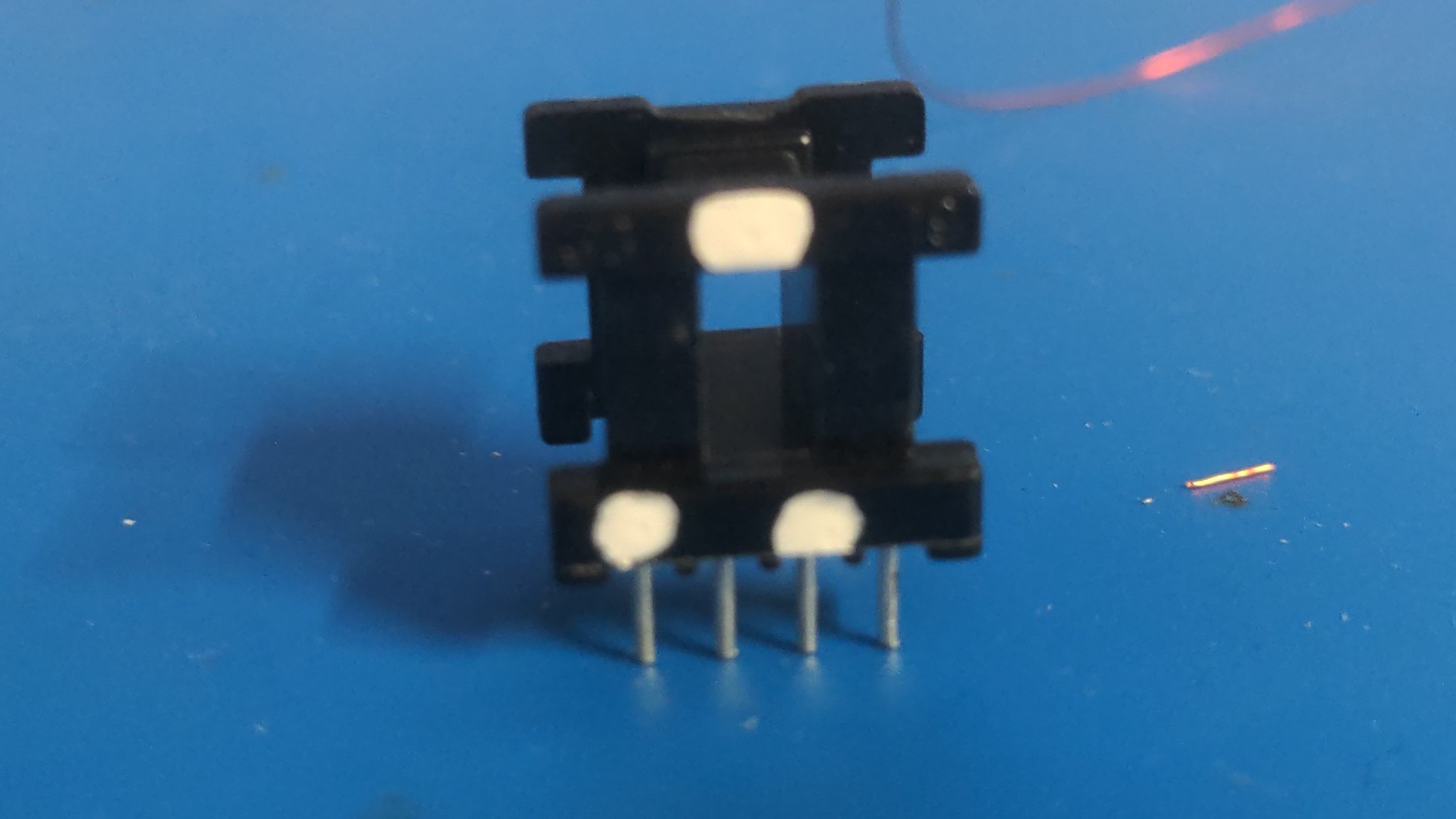

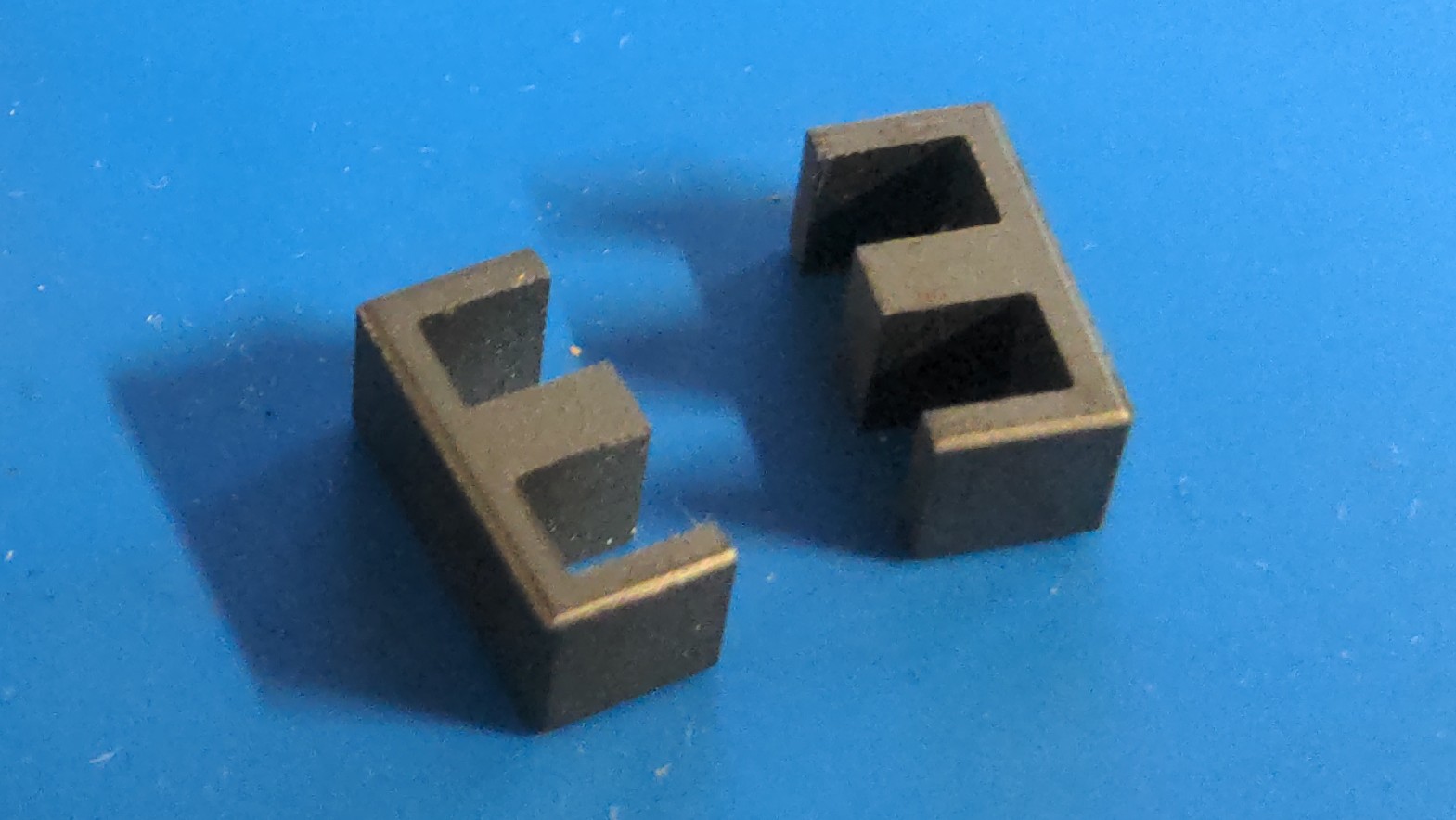

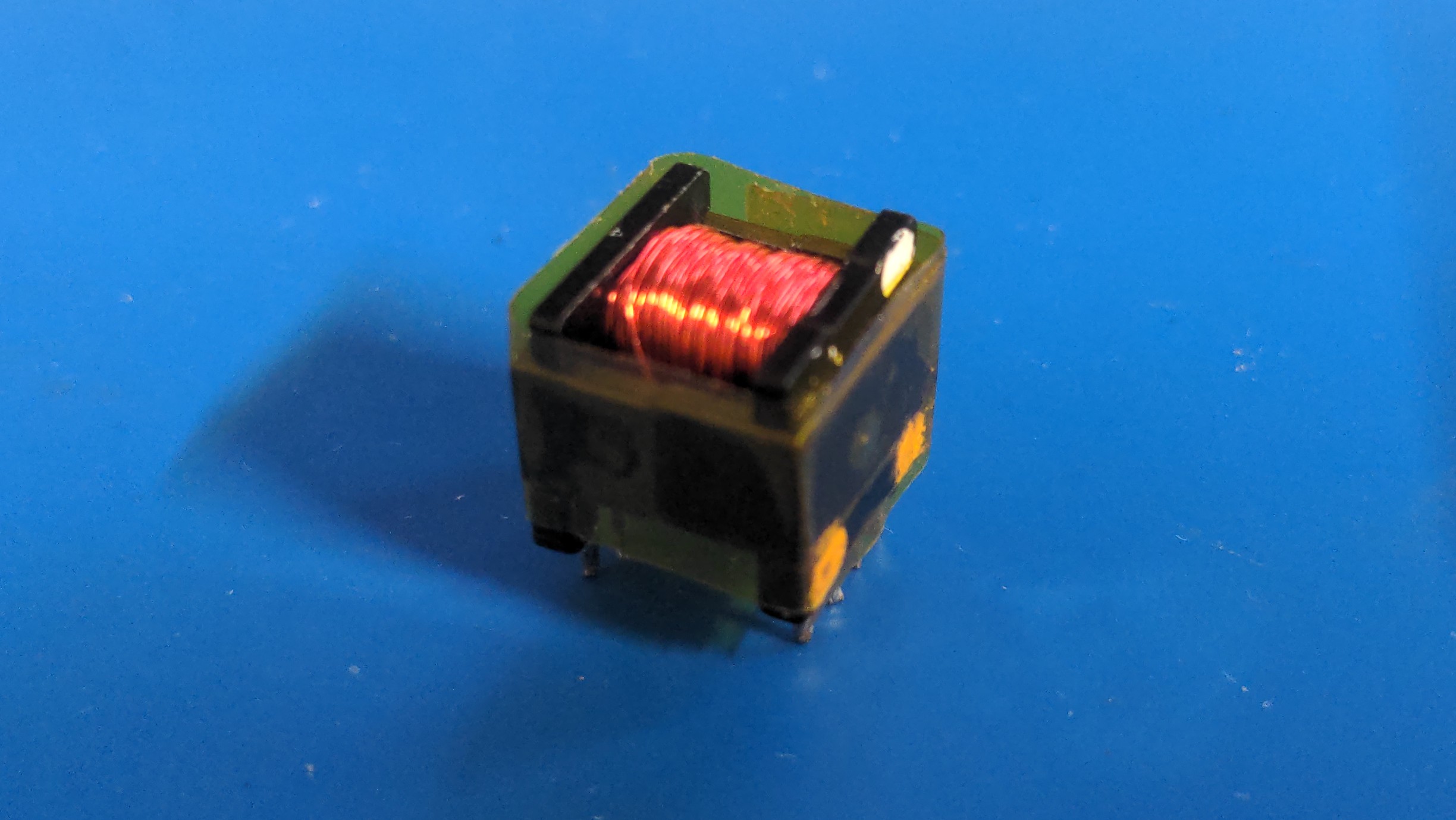

These cores will eventually be inserted into this bobbin.

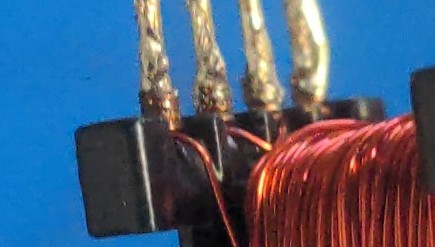

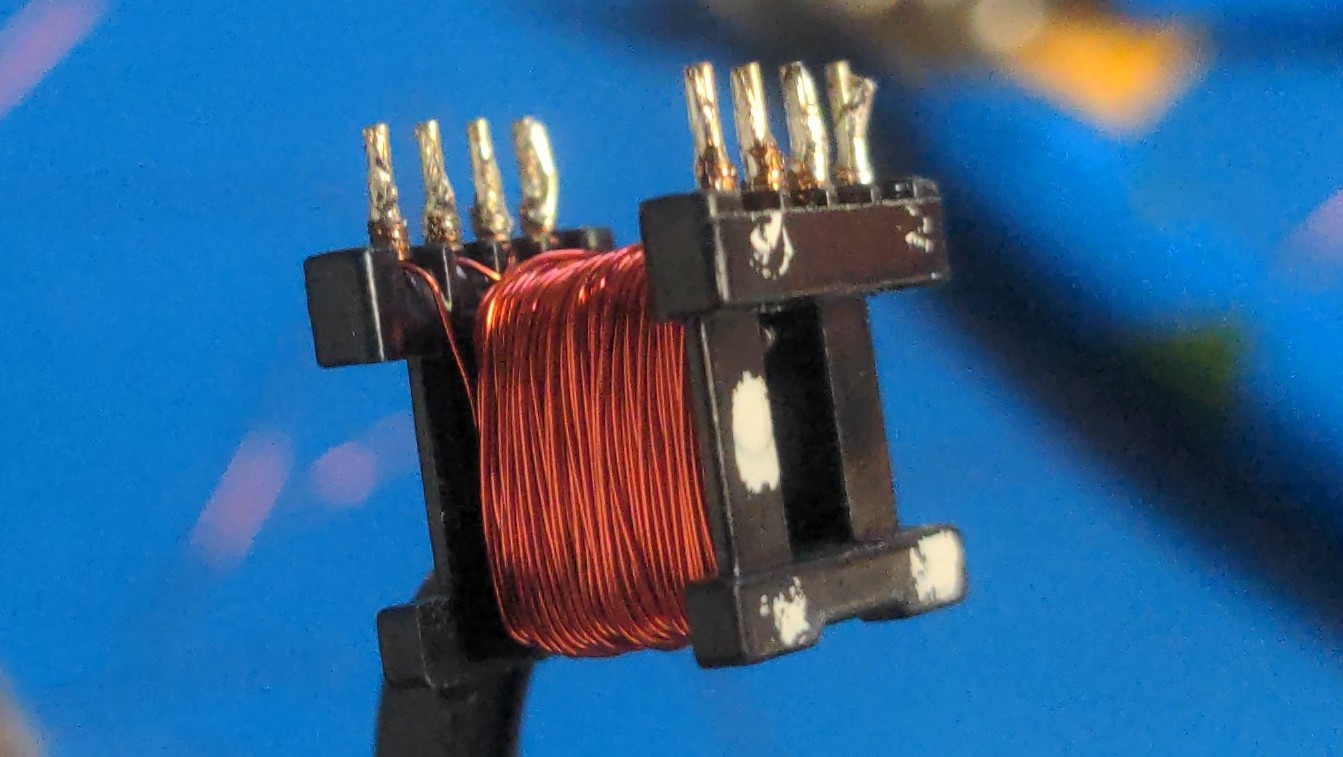

To connect the wires, the correct approach is to wrap the magnet wire around the pins, as much as feels appropriate. With 30 AWG wire, I instinctively wrapped each about four times. You can then wind the wire around the bobbin, before soldering.

When wrapping, ensure that the wires pass over this rounded strain relief section on their way away from the pins. This prevents the plastic from wearing away at the wire.

I was worried that the heat plus time required to burn away the enamel of the wire would melt the plastic of the bobbin. This seemed not be an issue. Very little solder is required, and it is easy to leave a lot of excess. It doesn’t particularly matter, though, because it is easy to clean up.

Here is a completely wound bobbin, before inserting the cores.

And here it is after the cores have been inserted and taped up with whatever I had laying around (kapton tape, here).

Being from AliExpress, information about the cores is lacking, and that which there is can be very difficult to parse. To find a value for AL for the cores and bobbin I had, I made an inductor with a known number of turns (arbitrary, I selected 20), and measured its inductance with my NanoVNA (approximately 110uH). In my case for these EE13 cores and bobbins, I found AL = L/N2 = 275nH/turn2.

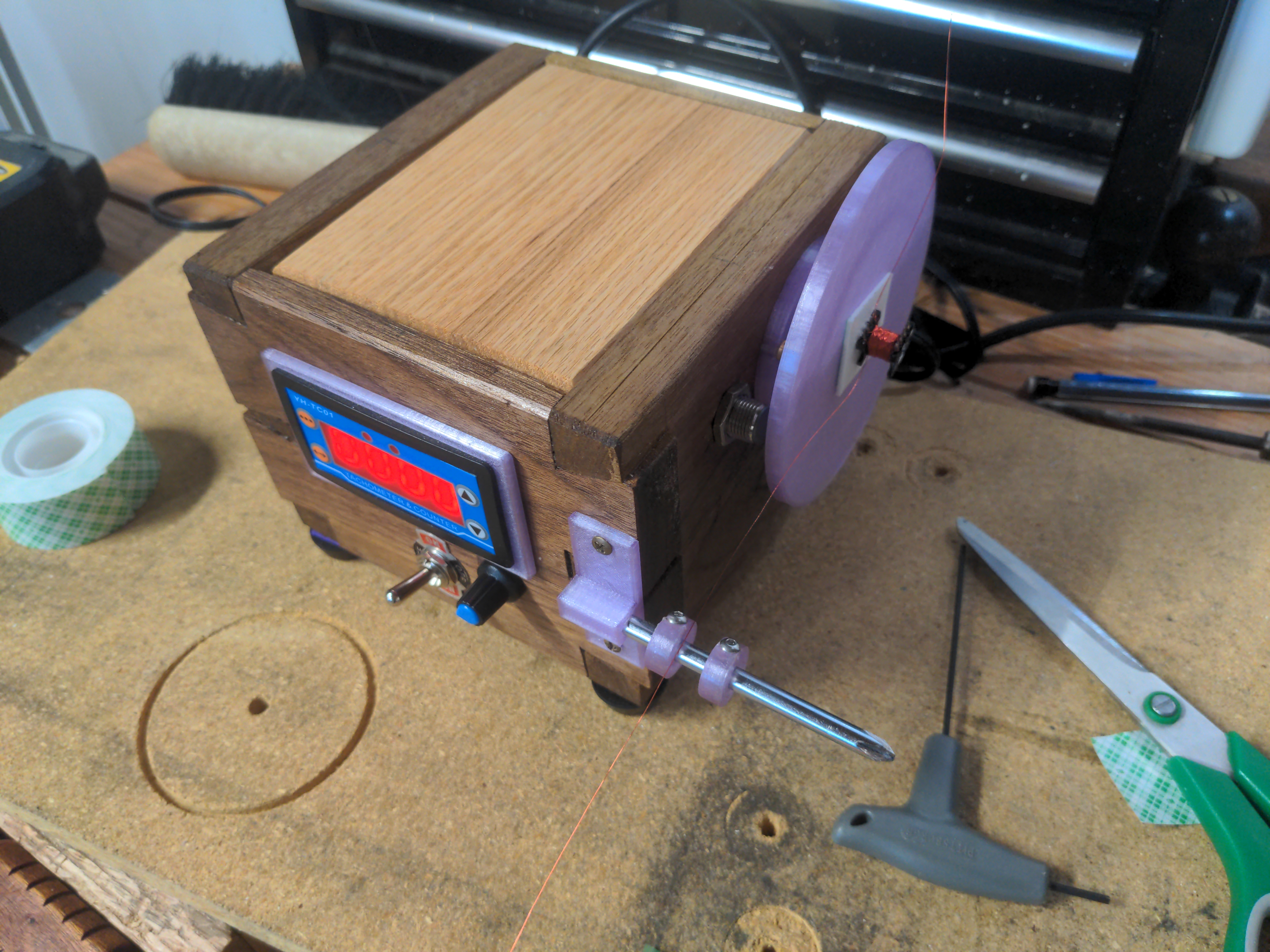

A machine to help with the process is very valuable. The guitar pickup winder my bugfriend had built worked decently for the process, however, using double sided sticky tape to attach the bobbin meant there was a lot of wobble, it was not in plane with the rotation of the motor, so winding can be tricky at points. Still clears winding by hand, though.

It is helpful to ensure that you mount the bobbin the exact same time each time you go to wind it, that way the phasing will be equivalent to which direction you ran the motor.